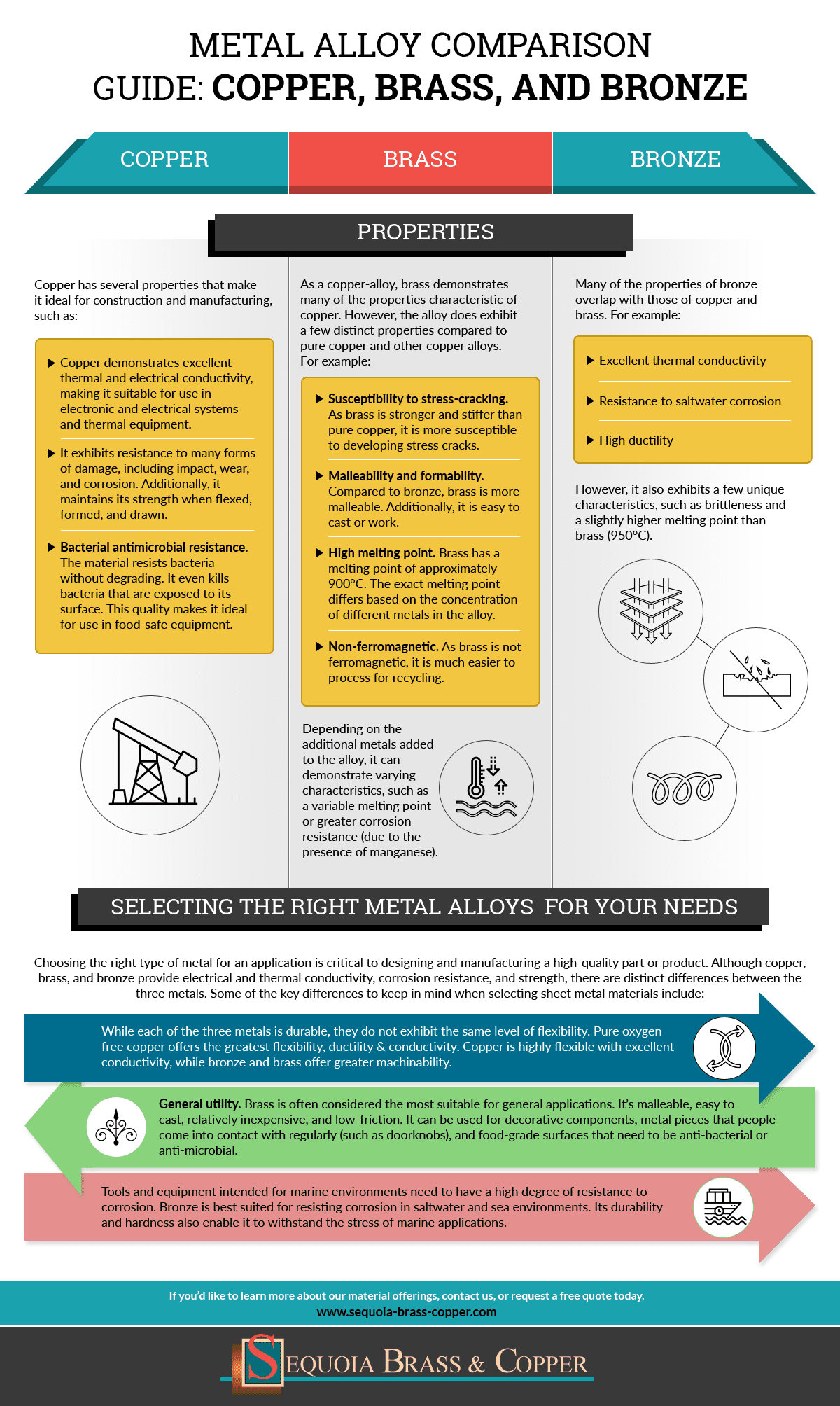

A great choice for transformers and circuit breakers or applications where conductivity is the key attribute.

Copper sheet material specification.

Bs b is an aerospace spec for copper alloys.

Note 1 each of the coppers listed has unique properties that can make it suitable for specific applications.

Copper sheet and copper plate find use in a huge array of applications.

Copper development association inc.

0 0323 0 0308 1 50 lb.

This specification 2 establishes the requirements for copper sheet strip plate and rolled bar produced from the following coppers.

System and description organization and contact info.

Standard designations for copper and copper alloys.

Society of automotive engineers 400 commonwealth drive warrendale pa 15096 phone.

Mechanical properties temper designation.

Standard specification for copper sheet strip plate and rolled bar.

Brass bars are now specified in bs en.

Standard specification for copper alloy plate and sheet for pressure vessels condensers and heat exchangers.

0 0431 0 0411 2 00 lb.

Bs b 11 was withdrawn in 1990 and not replaced.

B171 b171m 18.

0 0216 0 0204 1 00 lb.

The purchaser should consult with the supplier to determine which copper would be best suited for the intended application.

0 0270 0 0258 1 25 lb.

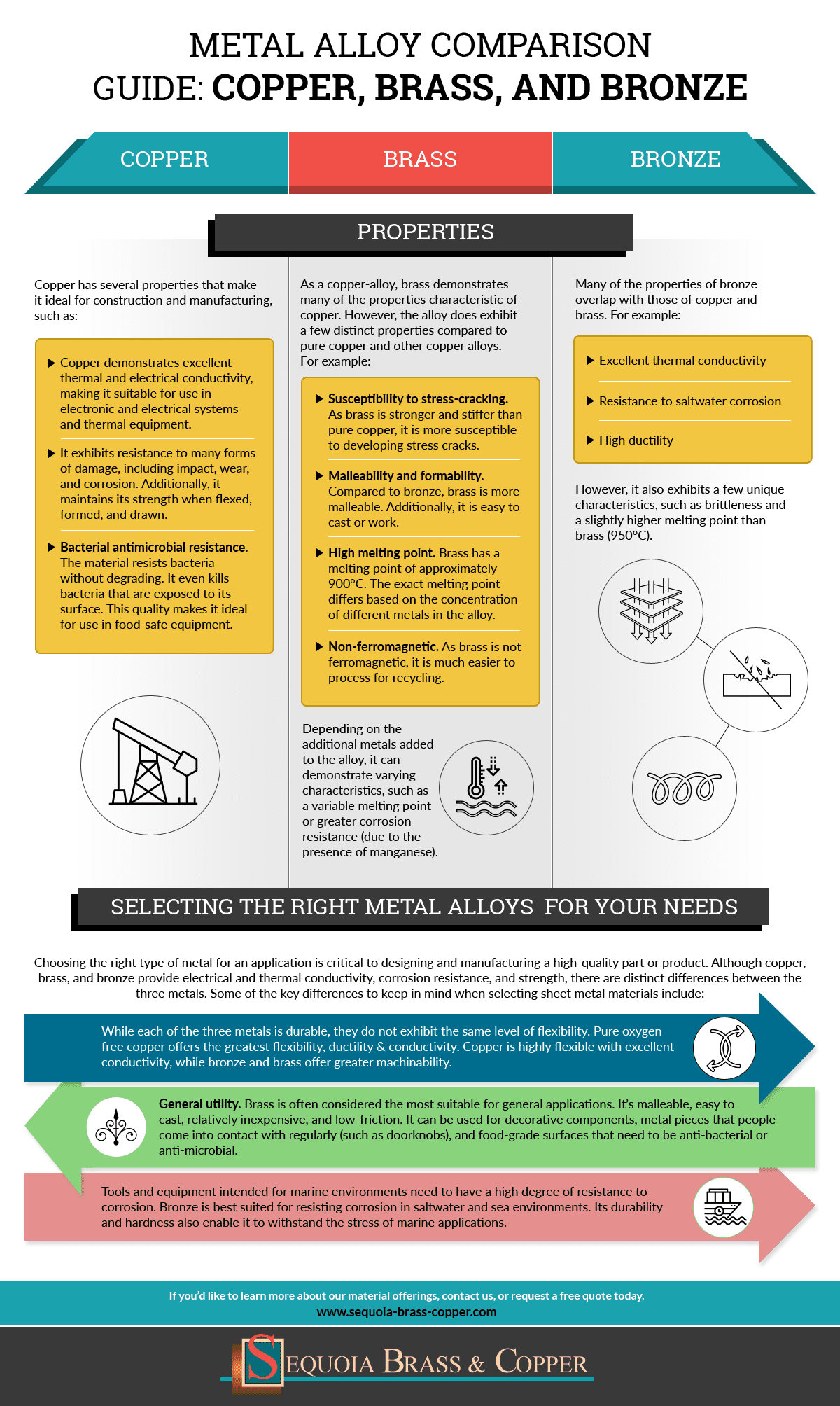

This means that it is pure and soft not only that but it is great to use in our everyday lives because it actually healthy as you ll see reading further below.

Bs b 11 is brass bars suitable to be brazed or silver soldered.

The number of the current european standard for copper tubes is bs en 1057.

Could you please identify an old brass specification bs b 11.

One of few metals that doesn t need to be extracted from ore i e it is directly usable in its natural state copper exhibits excellent thermal and electrical conductivity good ductility and a natural resistance to corrosion.

Copper material shall meet the maximum limit of electrical resistivity as indicated.

Cda 260 madison avenue 16th floor new york ny 10016 phone.

Electrolytic tough pitch etp c11000 copper strip is known for it s electrical and thermal conductivity properties along with good corrosion resistance and solderability.

The material shall undergo tensile strength rockwell hardness and plate item tests to conform with the mechanical proptery requirement of the specification.